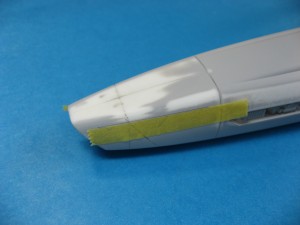

Starting to get close to paint time! One of the last major components to go on was the canopy (the guns are all that are left to go on, but they will be the last thing done, after final painting and weathering are finished). The canopy had some fit issues. The instrument panel sat a bit proud of the cockpit sill in the front, keeping the canopy from sitting level. After several sessions with a super fine file and attention to the top of the panel, I was able to get the canopy flush. Just to make sure it was all snugged up, while the glue set up, I clamped it from the top, but very carefully. Clear styrene is much more brittle than the other varieties, and the last thing I wanted to do was crack this transparency.

Starting to get close to paint time! One of the last major components to go on was the canopy (the guns are all that are left to go on, but they will be the last thing done, after final painting and weathering are finished). The canopy had some fit issues. The instrument panel sat a bit proud of the cockpit sill in the front, keeping the canopy from sitting level. After several sessions with a super fine file and attention to the top of the panel, I was able to get the canopy flush. Just to make sure it was all snugged up, while the glue set up, I clamped it from the top, but very carefully. Clear styrene is much more brittle than the other varieties, and the last thing I wanted to do was crack this transparency.

The black vinyl masks are from Aztek Dummy and specifically for this kit; the set also includes masks for painting the red stripes and markings, which I’ll do instead of using the kit decals. They pulled from the backing fine and laid down pretty well. I had to do some burnishing around the inner canopy frames to get them to completely adhere.

The final photo is of the Viper in overall primer gray. There are a few spots that need touched-up and polished out, and once that’s done it’s time for a little pre-shading and then the overall white coat.

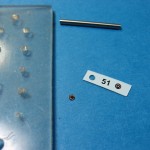

I’m reasonably sure that the fuselage is now ready for final primer and paint. That means that I have to get the canopy on and smoothed into the fuselage (it has gaps, of course), and to do that our pilot has to go in first. The kit instructions say if using the pilot, you are to cut off the top of the control stick and glue that to the bottom of the control stick already molded into the pilot’s hand. As you can see from the first photo, they don’t even come close to meeting up. Had I known of this issue before putting the cockpit into the fuselage, I would have built up the center console so that it looked right, but at this stage all I could do was drill out the base of the stick and put in a piece of wire to make up the difference.

I’m reasonably sure that the fuselage is now ready for final primer and paint. That means that I have to get the canopy on and smoothed into the fuselage (it has gaps, of course), and to do that our pilot has to go in first. The kit instructions say if using the pilot, you are to cut off the top of the control stick and glue that to the bottom of the control stick already molded into the pilot’s hand. As you can see from the first photo, they don’t even come close to meeting up. Had I known of this issue before putting the cockpit into the fuselage, I would have built up the center console so that it looked right, but at this stage all I could do was drill out the base of the stick and put in a piece of wire to make up the difference.

Long time no post. A trip out of town, a busy month at work, and the worst cold and subsequent respiratory virus I’ve had in years has kept me away from modeling. This is the first weekend in over a month that I’ve actually sat down to do some building. So, on with it…

Long time no post. A trip out of town, a busy month at work, and the worst cold and subsequent respiratory virus I’ve had in years has kept me away from modeling. This is the first weekend in over a month that I’ve actually sat down to do some building. So, on with it…

After a week away at an awesome writing retreat, and then returning to a 9-5 gig last week, the modeling time has been limited, but I still have made some progress.

After a week away at an awesome writing retreat, and then returning to a 9-5 gig last week, the modeling time has been limited, but I still have made some progress.

A few photos before I take a break. It’s time for the yearly

A few photos before I take a break. It’s time for the yearly

With the wind ripping out of the west today so hard that I’m not sure how parts of our building haven’t sailed off into the Hudson, there was no way I could set up the

With the wind ripping out of the west today so hard that I’m not sure how parts of our building haven’t sailed off into the Hudson, there was no way I could set up the

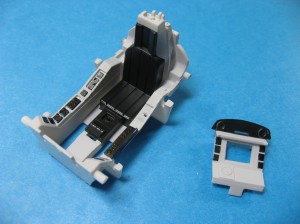

Since the cockpit gets sealed up inside the fuselage, I have to deal with it first. The photos below show the process. The five major components (2 sidewalls, tub with seat, instrument panel, and display) were cut out, cleaned up, and primed. The sidewalls had HUGE ejector pin marks in prominent positions, so I filled and sanded, primed, repeated as necessary. I then cut in and painted the black panels by hand, something I don’t normally do, but they were just too tiny to mask.

Since the cockpit gets sealed up inside the fuselage, I have to deal with it first. The photos below show the process. The five major components (2 sidewalls, tub with seat, instrument panel, and display) were cut out, cleaned up, and primed. The sidewalls had HUGE ejector pin marks in prominent positions, so I filled and sanded, primed, repeated as necessary. I then cut in and painted the black panels by hand, something I don’t normally do, but they were just too tiny to mask.