It’s been a while, just over 7 years since the last update. With more free time as of late (furloughed due to the Covid-19 crisis), I’ve been tackling some shelved projects. USS Chickasaw was put aside those years ago because… hell, I don’t remember why. But now, with CAD experience, and an in-house 3D printer, I have everything I need to finish her.

So far, the major work has been on body work, repairing seams that have cracked over the years, and prepping the hull for paint. I’ve been drawing all of the other components in CAD, using Rhinoceros v6, as I don’t have the original files for the turret, stack, screw, etc., and the prints of those items that I purchased from Shapeways years ago have degraded significantly.

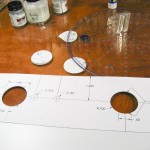

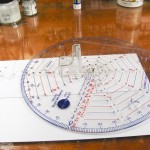

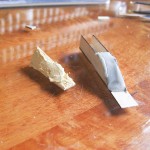

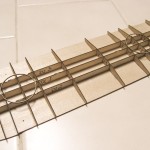

Here are a few photos of Chickasaw as she stands today.